Mould Makers

Our modern facility is backed up with a dedicated team of professional engineers

with a vast knowledge of the mould tool sector both in tool manufacture and design

to parts production and process.

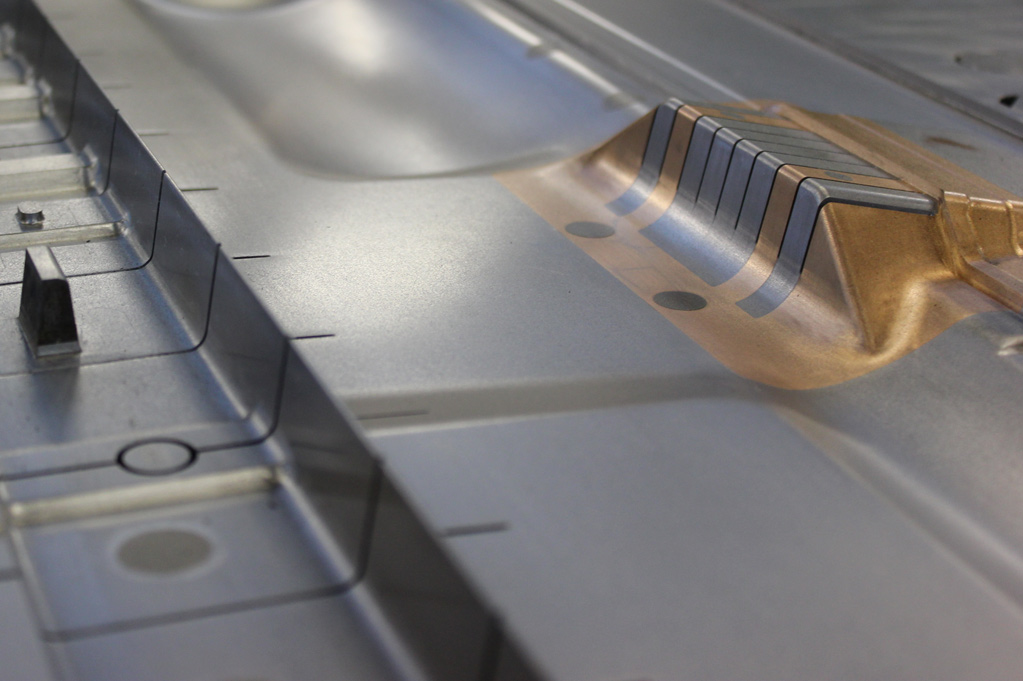

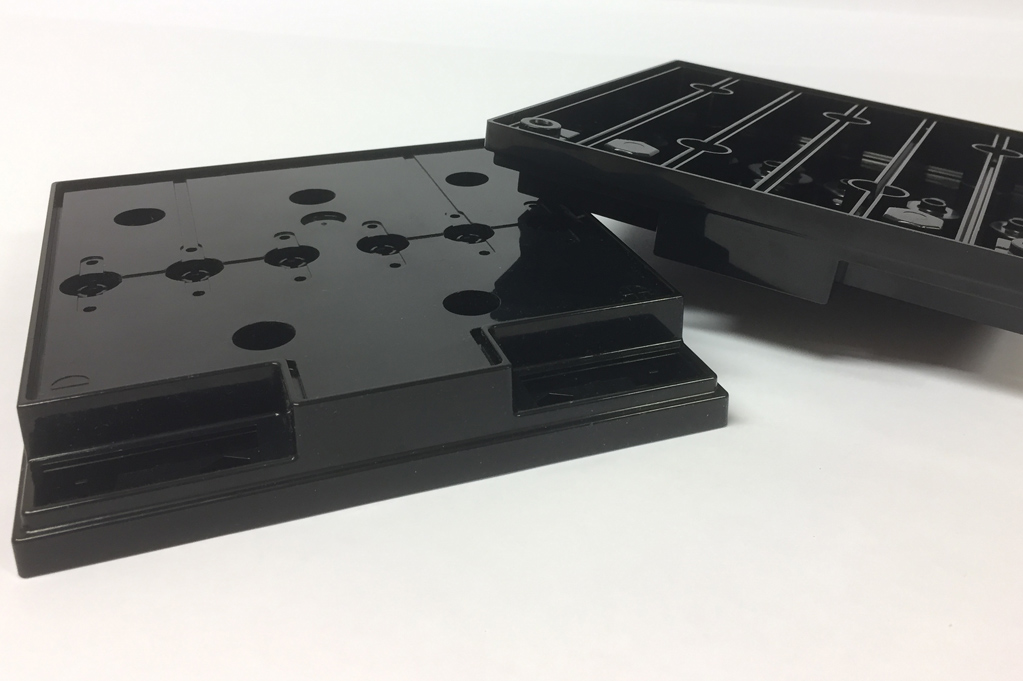

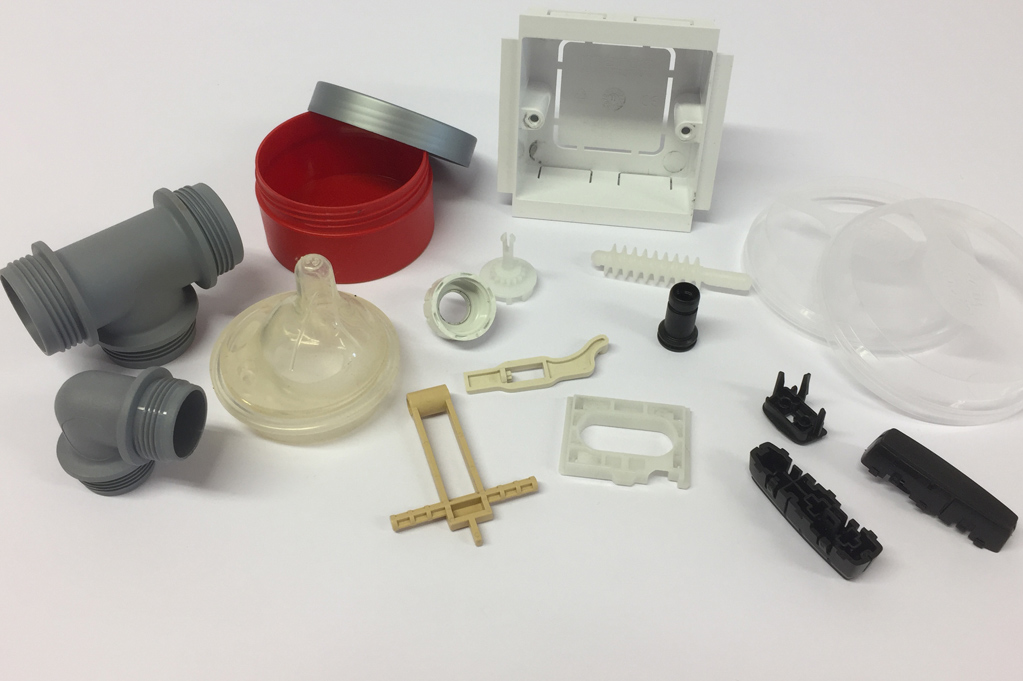

We specialise in tooling from 0.5 ton up to 10 tons in weight. These tools can be simple

single cavity tools, multi impression tools and twin shot tooling. Not only do we produce

injection mould tools but also compression tooling, manual moulds, transfer tooling and

investment casting tools.

Reverse Engineering

Our reverse engineering facility allows us to recreate your product, part or tool to exact standards.

The information is sent to our design team and then a model created which leads to the regeneration

of a new product or repaired part using our CNC Machining Facility and Tool room.

Investment tooling are happy to support you from design concept to

final PPAP, we support our customers with multi tool projects, turnkey solutions or one off

parts and assemblies.

Large Capacity

We have a large capacity and can handle small one off tools and multi tool / multi million pound projects, controlled by our project planners and project team members.

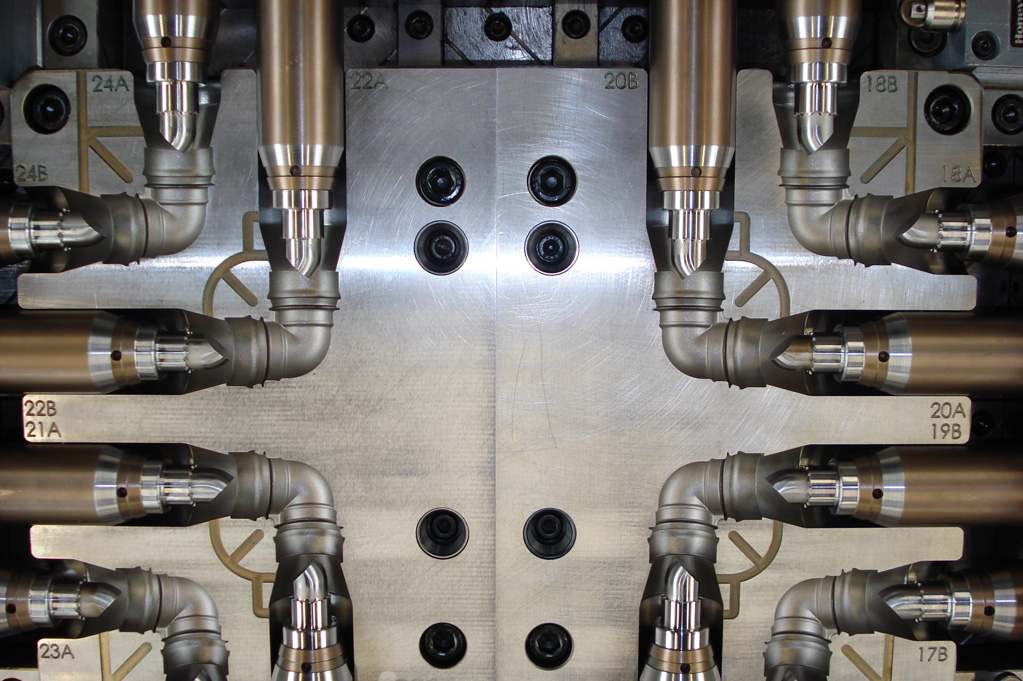

We have partners to support us with specialist steels, heat treatment, coatings, 3d printing and runner systems.

Not only do we produce, service and repair your tooling we can also trial your tools so they are fit for purpose when they arrive at your press.

Support Hours / Day

0Tools Upto (Kg)

0Machine Bed Size

0 X 0mmTool Makers

ITI Manchester is Here For You

Investment Tooling have a vast wealth of experience for you to tap in to, our team is ready to help and advise you from concept to product sign off. Please call us on 0161 653 8066 to speak to one of our members.